Where We Stand

Here at Versiclad we work to live. Our products create spaces for people to better enjoy life, so it’s no surprise that our values extend to a commitment of sustainability.

To maintain a greener approach to manufacturing, we first looked at the materials we use to develop our panels and how they impact the environment – starting with Expanded Polystyrene (EPS).

Understanding the Sustainability of EPS

There are some common misconceptions surrounding EPS because of its history of poor disposal. However, when properly handled, EPS is an incredibly sustainable material because it can be recycled up to seven times without deteriorating.

The manufacture of EPS uses less than 1% of global crude oil as a feedstock, yet it can deliver up to 200 times its own resource in thermal energy savings. To put this into perspective, the energy used to make EPS is recovered within six months by the energy saved in the buildings in which it’s installed.

What’s more is that the performance of the insulation does not deteriorate which suggests that the reduction of emissions begins at six months but continues for the lifetime of the building.

According to Expanded Polystyrene Australia (EPSA), this means that, with the right application, EPS insulation could reduce carbon dioxide emissions by 50%.

That being said, there’s no denying that there is an ongoing concern surrounding EPS ending up in landfill. So, in our constant pursuit of a circular economy, we started with accountability.

How We Do Our Part

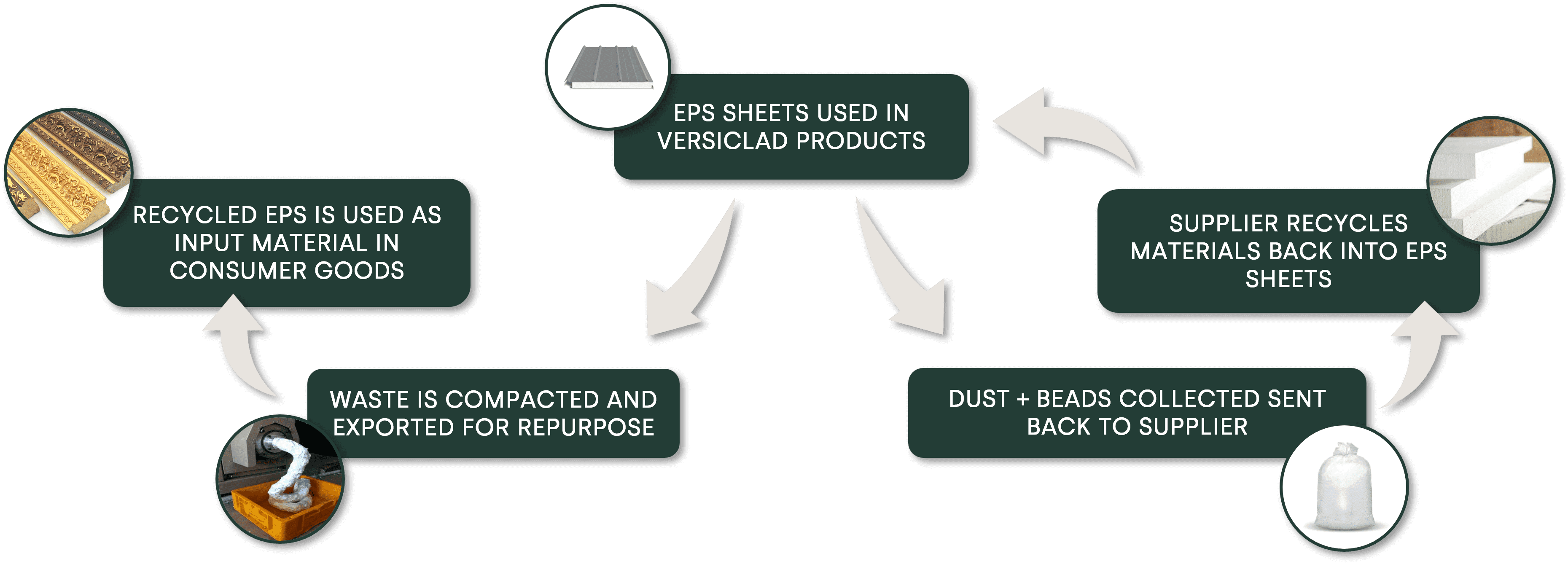

The lifecycle of our EPS material starts with our supplier who uses a non-CFC producing expansion agent to develop a 100% recyclable sheet. These sheets are then cut to size and sandwiched between metallic materials to create structural insulated panels. During this process, the dust and beads that are produced, are vacuumed into collection bags, and returned to our supplier to be recycled back into production.

Larger offcuts and waste are also processed through our densifier machine, which compacts the EPS to 90 times less than its original size. By compacting it, we allow for 90 times the available space in transport to further reduce carbon emissions and fuel consumption.

From there, our compacted EPS is exported to manufacturers in Europe and Asia as input materials in consumer goods such as kitchen and bathroom cabinetry, flooring/skirting products and picture frames.

Our Pledge

Our story begins with structural insulated panels that help to improve thermal comfort and reduce energy consumption. Our aim is to therefore, continuously improve our processes; to maintain regenerative and restorative practices and ensure our products are part of the solution.